Good Wear Resistance Tungsten Carbide Die / punching and impacting

die For Heading Industry , Long Lasting Time

1. Material: 100% virgin raw material with submicron grain size

2. Grade: Various grades for choice as per different application.

3. Precision Ground and polished

4. High wear resistance,high hardness and impact toughness

5. Advanced technology , automatic pressing , HIP sintering and

precision grinding

6. Sample order is acceptable.

Grades we recommend as blow:

YG11, YG15, YG20, YG16C, YG18C, YG22C, YG25C, GT55...

| Grade | Density g/cm3 | Hardness HRA | T.R.S MPa | Performance&application recommended |

| YG11 | 14.4 | 88.5 | 2420 | Forming or stamping dies for metal powders and nonmetal powders |

| YG15 | 14 | 87 | 3000 | It is suitable for drawing steel tubes and rods under high

compression ratio,manufacturing upsetting,punching and stamping

tools under large stress |

| YG20 | 13.5 | 85.5 | 2800 | It is suitable for manufacturing punching dies for watch parts,leaf

spring of musical instrument,battery jars,small sized steel

balls,screws,screw caps,etc |

| YG16C | 13.9 | 85 | 2750 | It is suitable for impact-resistant forging dies |

| YG18C | 13.7 | 84 | 2800 | It is suitable for impact-resistant forging dies,hot-forging dies

and finishing rollers |

| Other grades and sizes can be offered as per customers'

requirements |

| TYPE | some size of carbide punch press die/mm |

| d | D | L |

| BD0101015 | 10 | 1 | 15 |

| BD0171230 | 12 | 1.7 | 30 |

| BD0211015 | 10 | 2.1 | 15 |

| BD0211230 | 12 | 2.1 | 30 |

| BD0241015 | 10 | 2.4 | 15 |

| BD0291425 | 14 | 2.9 | 35 |

| BD0291640 | 16 | 2.9 | 40 |

| ... | ... | ... | ... |

1). Carbide punching and impacting die area is one of the main

applications of tungsten carbide material. Heading dies usually can

be divided into punching die and bushing die , used in cold

heading, warm heading and hot heading technology situation.

2). Carbide punching and impacting die is a process technology

which make the work piece transformation and the shape close to the

finished product to the utmost extent in few processes. It is the

milestone of modern mechining and automobile industry.

3). Why we need cold heading?

Carbide punching and impacting die improves the products'structure.

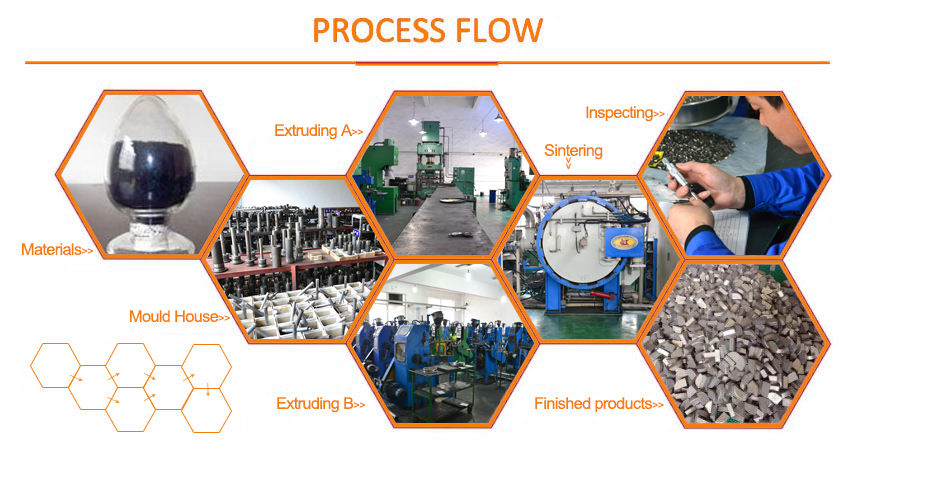

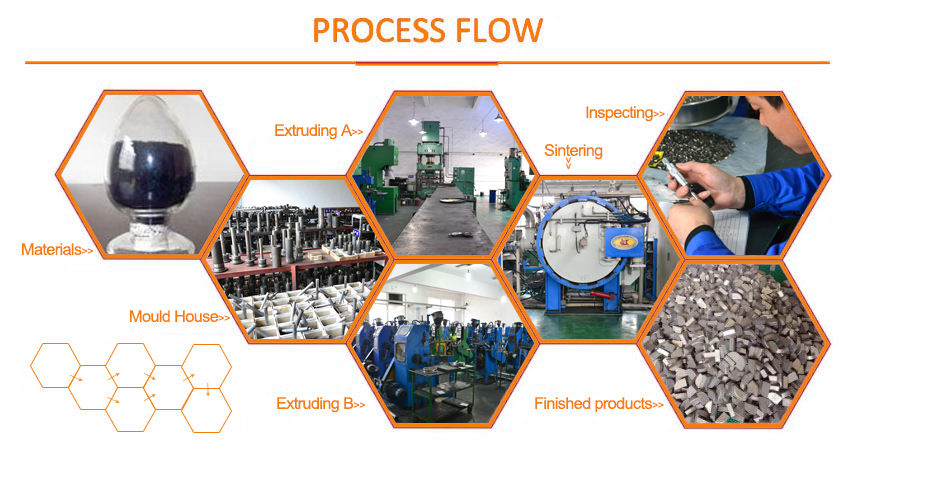

1, Soon after the order is confirmed, carbide die products will start to prepare the RTP powder as per customer’s

requirement with our wet-grinding machine

2, Before mass production, we need to do a trial pressing and

sintering using every mould, and we check the appearances and the

sizes of carbide die samples with micrometer, projectors etc. to ensure that the

requirements of the drawings can be met before batch production

3, Bulk production ,press the raw materials to shape blanks,and all carbide die blanks must be passed by semi finished inspection,

4, Then sinter blanks to finish (HIP) and finished products

inspection, we have 10 sets of vacuum sintering furnace and 2 sets of HIP in

the factory ensure the best quality and production capacity.

5, 1). cleaning/tumbling is to make the carbide die look more beautiful.

2).The carbide die can be ground according to customers’ order to a tolerance of

+/-0.05

We are a carbide products manufacturer for over 18 years history.

We gain a professional team in tungsten carbide area.

OEM/OEM are acceptable.

We offer best before sale and after sale service.

We joined Alibaba Trade Assurance to make sure the buyer’s benefit.

If can’t meet the details in the contract, 100% of your payment

will be returned.

As a professional manufacturer, we have 18 years factory experience

for Carbide punching and impacting die. We are devoting to the

research and manufacturing of many different type and size.

ou can see from the below picture that many customers visited our

exhibition booth, more and more customers in the world are using

our Carbide punching and impacting die , we received many good

feedbacks or reviews from lots of countries.